ROCSOLE™ has a broad IP portfolio with worldwide granted patents. We are backed by Shell Ventures, Repsol Energy Ventures, Equinor Energy Ventures as well as the Finnish TESI investment company.

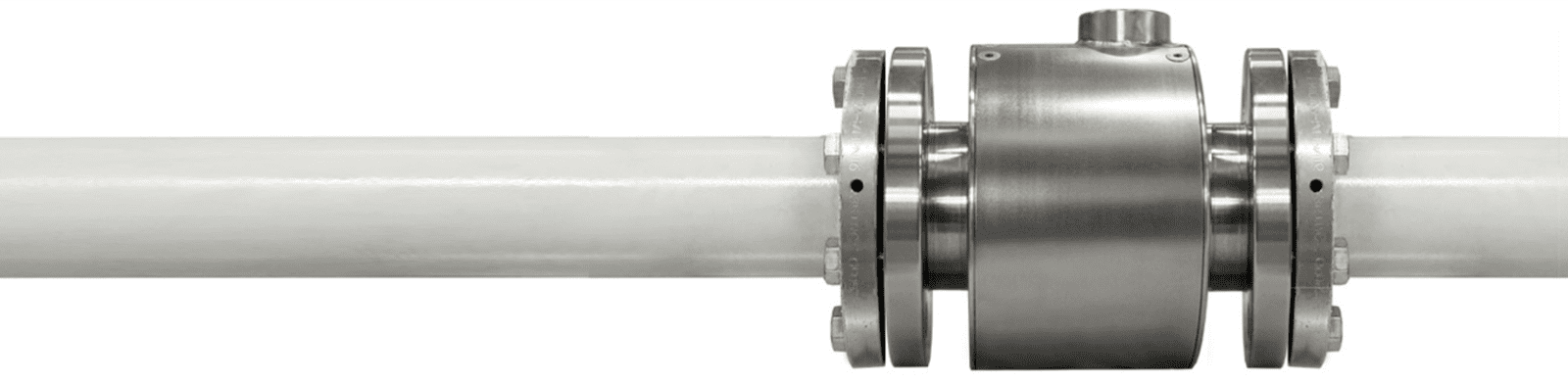

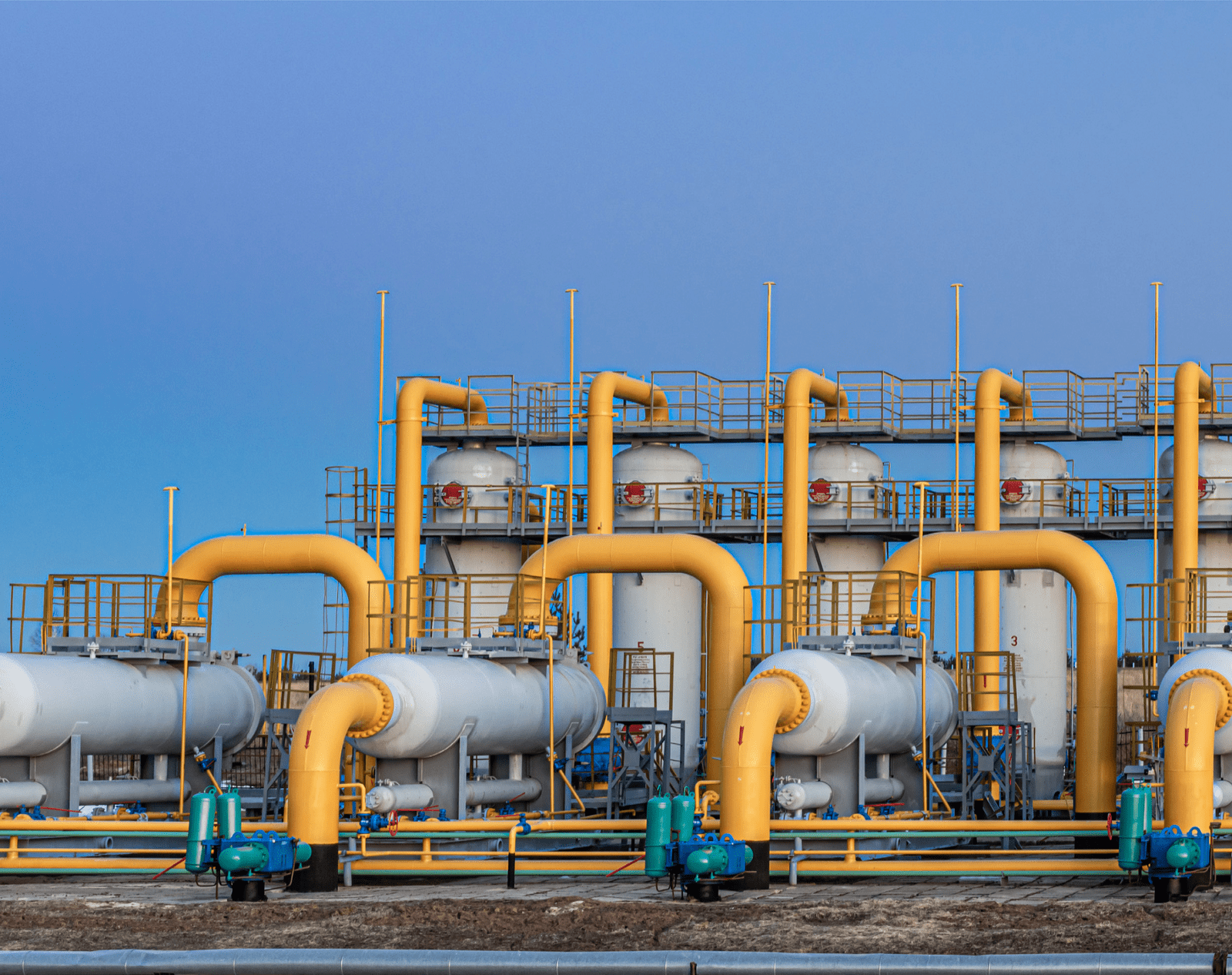

PIPELINE MONITORING

How costly is an unplanned pipeline shut down?

Can we see and measure pipeline deposits in real-time?

What is the possibility of water-cut measurements when no mixing is available?

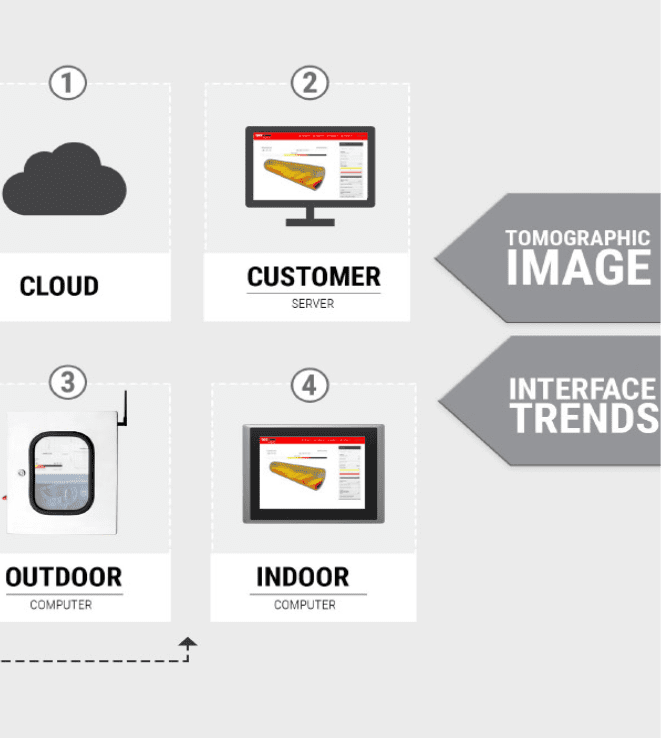

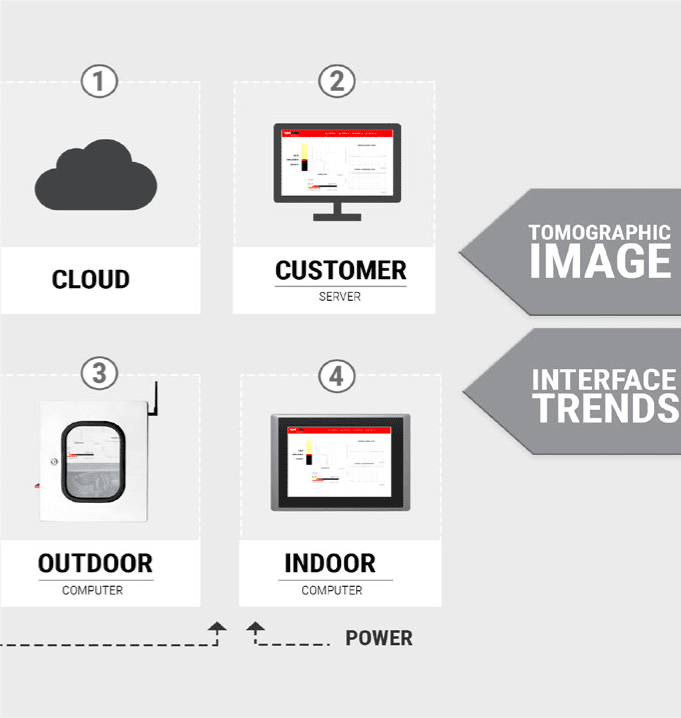

Pipelines are critical assets to the various segments of the Oil&Gas industry. The ability to see the inside of pipelines in real-time has been a dream of the industry. ROCSOLE’s Electrical Tomography based SEE BEYOND technology, is the answer that is sure to make measurable savings for the operators. Considering the costs involved and the rising demand for energy efficient operations, real-time process insights linked to pipeline deposits and un-detected water and gas slugging are highly valuable. ROCSOLE provides a variety of services and data analytics to improve the business value of the customer. These solutions can be provided as an integration into the existing control systems or as cloud-based SaaS Services.

PERFORMANCE

| Technology | Electrical Tomography | Resolution | 11 - 12 mm (0.43 - 0.87") |

| Accuracy / Precision | Application dependent | Pressure Range | Up to 242 bar (3520PSI) |

| Typical Diameters | 2" - 10" | Temperature Range | Up to 175°C (350°F) |

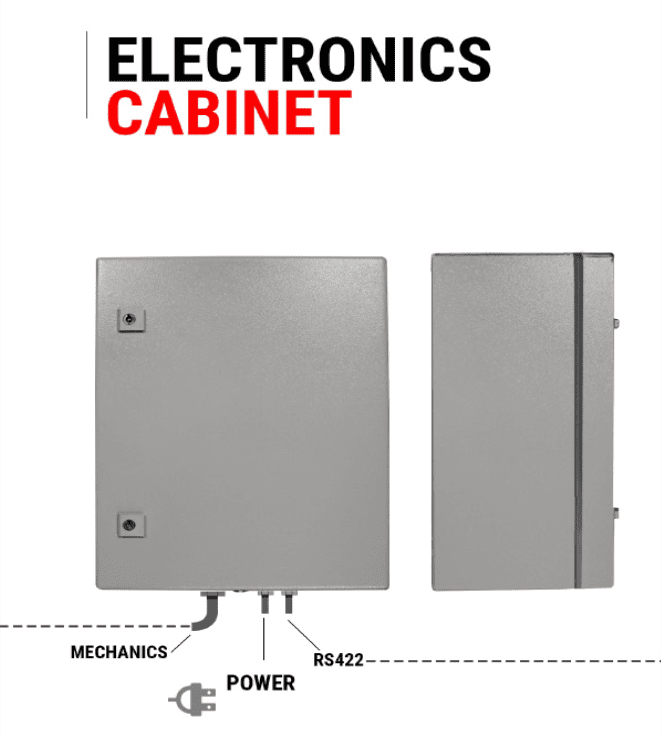

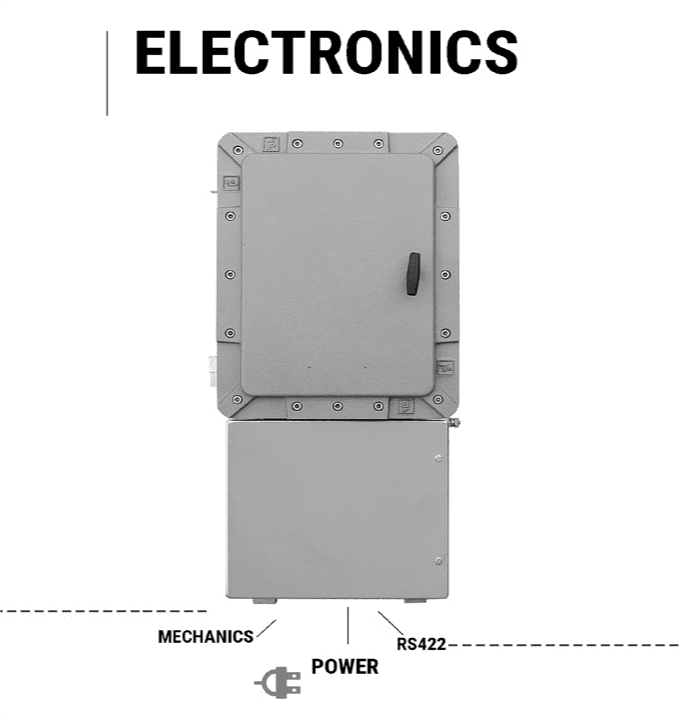

ELECTRICAL CHARACTERISTICS

| Supply Voltage | 24VDC | Output | - Modbus /TCP |

| Electronics | 24VDC @3A | - Modbus/RTU (R5485 & R5232) | |

| Computer | 24VDC @3A | | - Analog 4 - 20mA |

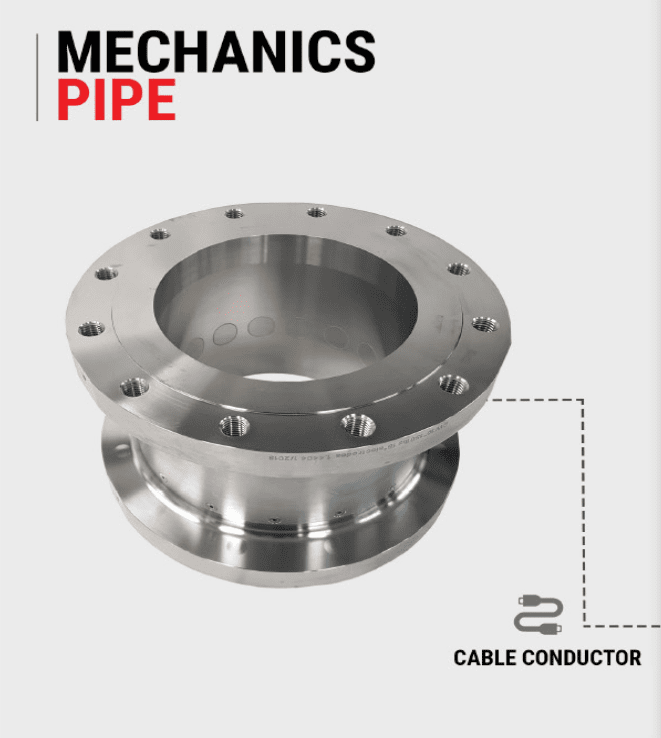

MECHANICAL CHARACTERISTICS

| Weight | Material | Zone | |

|---|---|---|---|

| Pipe | Varies | Varies | Zone 0 |

| Electronic Cabinet | 44.9 - 76.8 Kg | Varies | Zone 1 |

| Computing Unit | 30 Kg | SS 1.4404 (AISI 316L) | Safe Zone |

ENVIRONMENTAL

| Approvals | ATEX, IECEx, CSA (Optional) | Operating Temperature Sensor | - 40 ... + 175°C |

| Method of Protection | No Special needs | Operating Temperature Electronics | - 40 ... + 50°C |

| Installation | With online factory support | Operating Temperature Computing Unit | - 40 ... + 50°C |

| Compliance | EN | System Storage Electronics | - 40 ... + 65°C |

ADDITIONAL INFORMATION

| Spares | Separate list, please ask SECO |

| Product Code | PIPE-8 ..64 |

| Software | Rocsole Webroc |

PIPE APPLICATION

Key Features

- Reliable and real-time measurement

- Works in conductive and non-conductive fluid media

- Pipeline deposits, Flow regime visualization and water-cut all in one sensor

- Full cross-sectional measurement – SEE the “big picture”

- Signals are always backed up with 3D imaging

- Sensor works even when contaminated

- Material of the deposit can often be identified

- Different phases flowing can be differentiated

- Works in multiphase flow regimes

- Water-cut can be measured in difficult flow conditions

- AI based trending of the data

BENEFITS

- Optimize pigging requirements and pipeline cleaning

- Helps to validate pigging efficiency

- Prevent unplanned shut downs

- SEE BEYOND helps to utilize the full pipeline capacity

- No re-calibrations required

- No radioactive sources involved and is completely safe

- Easy user-interface, integrates into existing control systems

- Detailed data analytics available

- Customized reporting available

PORTABLE TESTING SOLUTIONS

How do you evaluate in real-time:- well fluid behavior?

- solids production?

- slugging?

- emulsion stability?

PORTABLE EQUIPMENT

KEY FEATURES

- Fully equipped and portable system

- Onsite/online support available

- Only power required

- Integrated SCADA with logging, reporting and communication functionalities

- Suitable for hazardous areas

- Suitable for well testing, process diagnostics & optimization

- Leasing available

BENEFITS

- Real time evaluation for liquid levels, emulsion valuation and solid accumulations

- Fast data reporting in multiple formats available online

- Allows testing in real environment with low investment cost

- Rapid and reliable way to verify process conditions and system design

- No sampling required

SEPARATOR PROFILING

- Are you struggling to maintain export oil specifications or

- oil-in-water quality?- Is your chemical expenditure continuing to rise?

- Do you have shut-in production that you cannot handle?

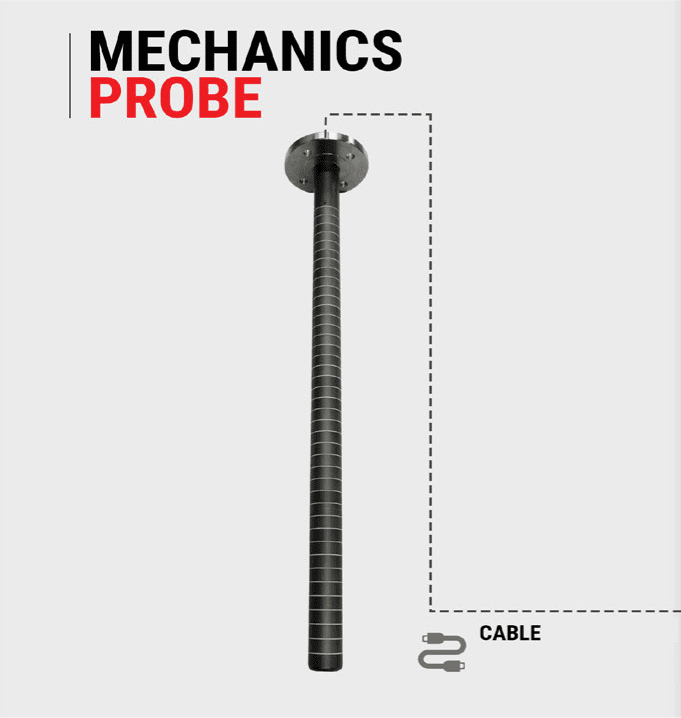

PERFORMANCE

| Technology | Electrical Tomography |

| Level Accuracy | ± 1% (application specific) |

| Typical Measurement Range | 180 - 2880mm (7 - 113") |

| Typical Total Length | 200 - 5000mm (8 - 200") |

| Minimum Nozzle Size ID | 40mm (2") |

| Pressure Range | Up to 207 bar (3000PSI) |

| Probe Temperature Range | Up to 175°C (350°F) |

| Resolution | 11 - 22mm (0.43 - 087") |

KEY FEATURES

- Full vessel profiling (gas, liquids, solids)

- Works contaminated

- Detailed analysis of emulsions

- Rapid analysis (10 cycles per second)

- No re-calibration required

- Signals are always backed up with 3D imaging

BENEFITS

- Reliable level control - prevents unplanned shutdowns

- SEE BEYOND allows operations when contaminated

- No re-calibrations required

- No radioactive sources involved and is completely safe

- Easy user-interface, integrates into existing control systems

- Detailed data analytics available

- Customized reporting available

ENVIRONMENTAL

| Approvals | ATEX, IECEx, CSA (Optional) | Operating Temperature Sensor | -40 .. +175°C |

| Method of Protection | No special needs | Operating Temperature Electronics | -40 .. +50°C |

| Installation | With online factory support | Operating Temperature Computing Unit | -40 .. +50°C |

| Compliance | EN | System Storage Temperature | -40 .. +65°C |

ADDITIONAL INFORMATION

| Spares | Please contact us |

| Product Code | PROB-8..64 |

| Software | Rocsole Webroc |

SAND MANAGEMENT

How much is sand production costing us?How do we manage our sand production?

PERFORMANCE

| Technology | Electrical Tomography |

| Level Accuracy | ± 1% (application specific) |

| Typical Measurement Range | 180 - 2880mm (7 - 113") |

| Typical Total Length | 200 - 5000mm (8 - 200") |

| Minimum Nozzle Size ID | 25mm (1") |

| Pressure Range | Up to 690 bar (10 000PSI) |

| Probe Temperature Range | Up to 175°C (350°F) |

| Resolution | 11 - 22mm (0.43 - 087") |

ELECTRICAL CHARACTERISTICS

| Supply Voltage | 24VDC |

| Electronics | 24VDC @3A |

| Computer | 24VDC @3A |

| Output | - Modbus/TCP |

| - Modbus/RTU (RS485 & RS232) | |

| - Analog 4 -20mA |

MECHANICAL CHARACTERISTICS

| Weight | Material | Zone | |

|---|---|---|---|

| Probe | Varies | Varies | Zone 0 |

| Electronics Cabinet | 44.9 - 76.8 Kg | Varies | Zone 1 |

| Computer Unit | 30Kg | Varies | Safe Zone |

ENVIRONMENTAL

| Approvals | ATEX, IECEx, CSA (Optional) | Operating Temperature Sensor | -40 .. +175°C |

| Method of Protection | No special needs | Operating Temperature Electronics | -40 .. +50°C |

| Installation | With online factory support | Operating Temperature Computing Unit | -40 .. +50°C |

| Compliance | EN | System Storage Temperature | -40 .. +65°C |

ADDITIONAL INFORMATION

| Spares | Please contact us |

| Product Code | PROB-8..64 |

| Software | Rocsole Webroc |

KEY FEATURES

- Reliable method for evaluation of solids in the upstream production

- Compact design for production vessels including slug catchers, manifolds and test separators

- Easy to retrofit to existing vessels

- Reliable method to evaluate field wide sand production and accumulation

- Applicable for full life of field use

- Real time monitoring and reporting

- Sensor works even when contaminated with wax, asphaltenes

- Real-time and accurate measurement

- Fully compatible and can be integrated into asset management systems

- Measurement data backed up with real-time 3D-imaging

- Potential to differentiate solid deposits

BENEFITS

- Avoid costly unplanned shutdowns

- Maintain production capacity of the

- process system

- Real-time, reliable data

- Easy to install into existing vessels, suitable for high pressures and different nozzle sizes

- Can be installed in multiple orientations

- No re-calibration required

- Customized reporting available

- User-friendly interface