Inline process density and viscosity monitoring and control

Inline process density and viscosity monitoring and control

Rheonics density meters and viscometers are available as probes and flow-through systems for installation in tanks, process lines and reactors and also brings fluid intelligence and process control to broad range of customer applications.

All Rheonics products are designed to withstand harshest process enviroments, high temperature, high level of shock, vibrations, abrasives & chemicals.

SRV

Ultra high accuracy simultaneous density and viscosity metering

- Single instrument for simultaneous process density, viscosity and temperature

- Monitor even gas density and viscosity

- Accurate measurement in the harshest of conditions

- Operational to 1000 bar and 200°C (15000 psi, 400°F)

- Full Titanium construction

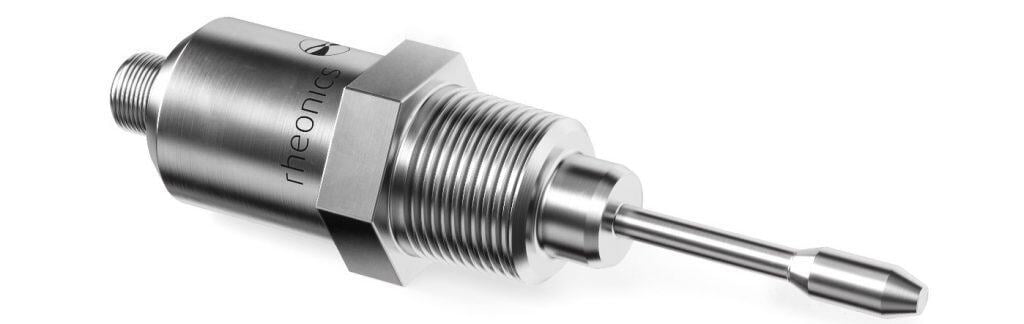

SRD

Single instrument combining HPHT Density meter and Viscometer

- Single instrument for simultaneous process density (specific gravity), viscosity and temperature measurement

- Compact form-factor for simple installation

- Real-time, stable, repeatable and reproducible measurements in Newtonian & non-Newtonian fluids

- Measures kinematic and dynamic viscosity

- All metal (316L Stainless Steel) construction

- Completely insensitive to mounting conditions

- Operational to 500 bar and 300°C (7500 psi, 575°F)

- Threaded, flanged and sanitary process fittings

- Easy to clean, no maintenance or re-configurations needed

- Scale across multiple locations/installs without application re-engineering

DVP

Wide-range inline process Viscometer

- Compact form-factor for simple installation

- Real-time, stable, repeatable and reproducible measurements in Newtonian & non-Newtonian fluids

- Track viscosity change over wide range with one sensor

- All metal (316L Stainless Steel) construction

- Completely insensitive to mounting conditions

- Built in fluid temperature measurement

- Operational to 500 bar and 300°C (7500 psi, 575°F)

- Easy to clean, no maintenance or re-configurations needed for scaling across the factory

.

DVM

Inline process density meter and viscometer

- Simultaneous density, viscosity and temperature measurement

- Measure at reservoir conditions: 30,000 psi and 400°F (2000 bar and 200° C)

- Built for on the bench or in the field use

- Extremely accurate measurement in the harshest of conditions

- 5 minutes from box to operation in your flow loop – built to integrate with all PVT systems

- Full Titanium construction