Excellence in Precision Engineering Solutions

Excellence in Precision Engineering Solutions

RAC Bonetti is an Italian-based manufacturing company established in 2014, specializing in high-quality valves and level gauges for critical sectors such as power, chemical, petrochemical, pharmaceutical, food, and oil & gas. The company's diverse product range includes gate, globe, check, piston, triple offset butterfly valves, and custom-designed valves suitable for high-pressure and high-temperature applications. RAC Bonetti also produces liquid level gauges, including glass, magnetic, and electronic types, available in both standard designs and bespoke solutions tailored to meet specific fluid pressure and temperature requirements.

Key Areas of Expertise and Product Offerings:

- Valves: RAC Bonetti manufactures a wide range of valves, including gate, globe, check, piston, and triple offset butterfly valves. These valves are designed for use in high-pressure and high-temperature environments, ensuring optimal performance and longevity.

- Level Gauges: RAC Bonetti offers various types of level gauges, such as glass, magnetic, and electronic models, all available in standard configurations or custom designs to cater to the specific needs of fluid pressure and temperature applications.

- Customized Solutions: The company specializes in providing tailor-made solutions for customers, ensuring that products meet the exact specifications for unique and challenging fluid control systems.

Acquisition of Cesare Bonetti Brand:

In 2018, RAC Bonetti expanded its capabilities by acquiring the Cesare Bonetti brand, which included all trademarks, patents, licenses, models, know-how, machinery, and warehouse assets. This acquisition made RAC Bonetti the sole owner of the Bonetti brand, enabling it to continue offering valves and level gauges that adhere to the original Bonetti designs. The move further solidified RAC Bonetti’s position as a trusted supplier of premium valves and level gauges.

Manufacturing Facilities:

RAC Bonetti operates from two key production units:

- Valves Division: Located in Bonate Sopra, this facility spans approximately 2,500 square meters and specializes in producing high-quality valves for various industries.

- Level Gauges Division: Situated in Solaro, this facility also covers 2,500 square meters and focuses on the manufacture of reliable and innovative liquid level gauges.

Global Presence and Commitment to Quality:

RAC Bonetti has built a strong global presence, serving clients worldwide with its advanced solutions. The company remains committed to maintaining high standards of quality by adhering to industry regulations and ensuring that all products perform reliably in demanding applications. RAC Bonetti's customer-centric approach ensures that each client receives tailored solutions that enhance performance, efficiency, and safety.

Through continuous innovation and a deep commitment to excellence, RAC Bonetti continues to provide reliable, high-performance valves and level gauges, making it a trusted partner for a wide range of industries worldwide.

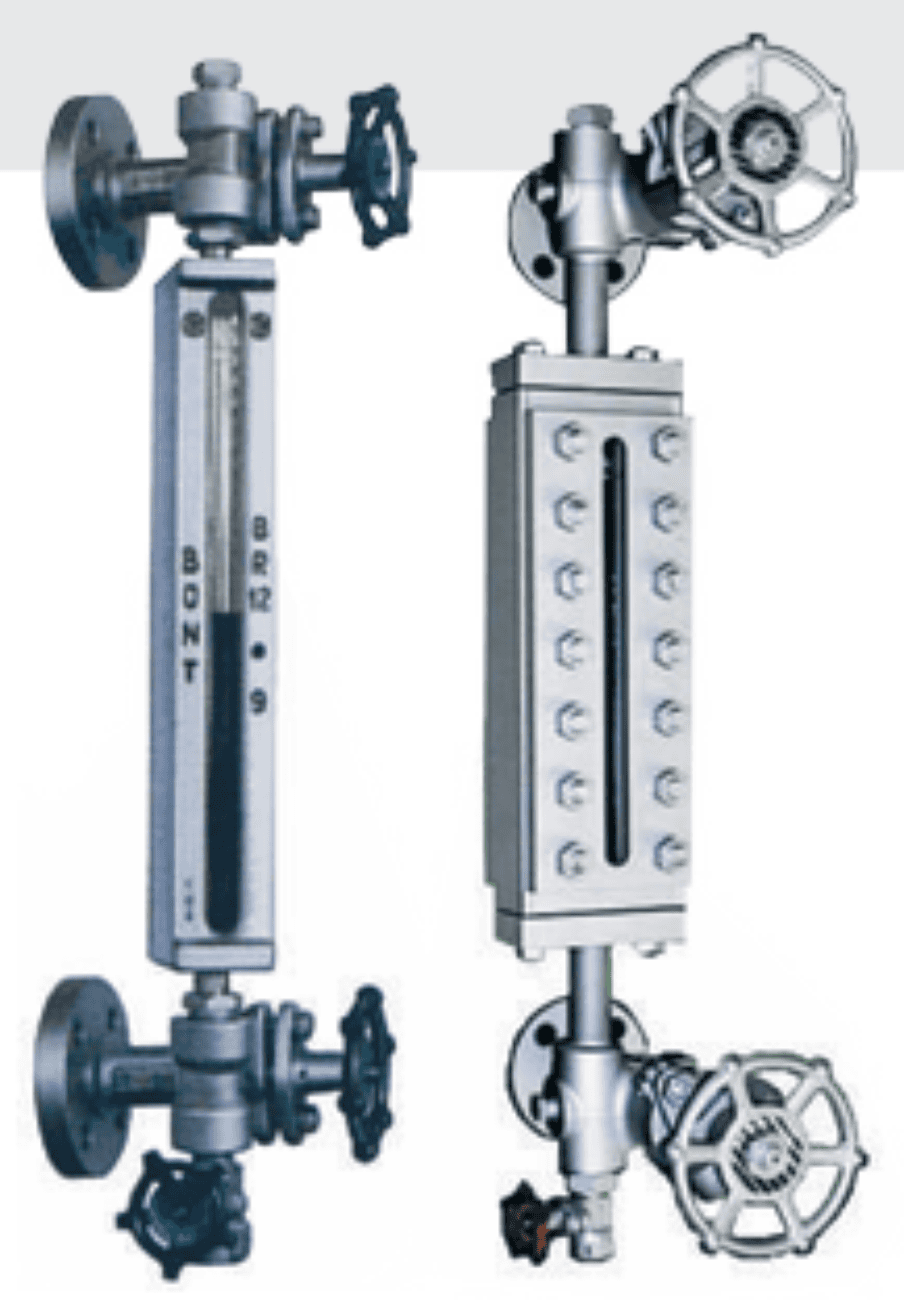

Direct reading level gauges series BT & BR

FOR USE WITH ANY FLUID With transparent or reflex glasses All materials construction, including: carbon steel, stainless steel, special alloys, plastics Rating: ASME Class 150 to 2500 (from PN 6 to PN 420) OPTIONS: antifrosting blocks, heating, illuminator (also explosion proof), etc

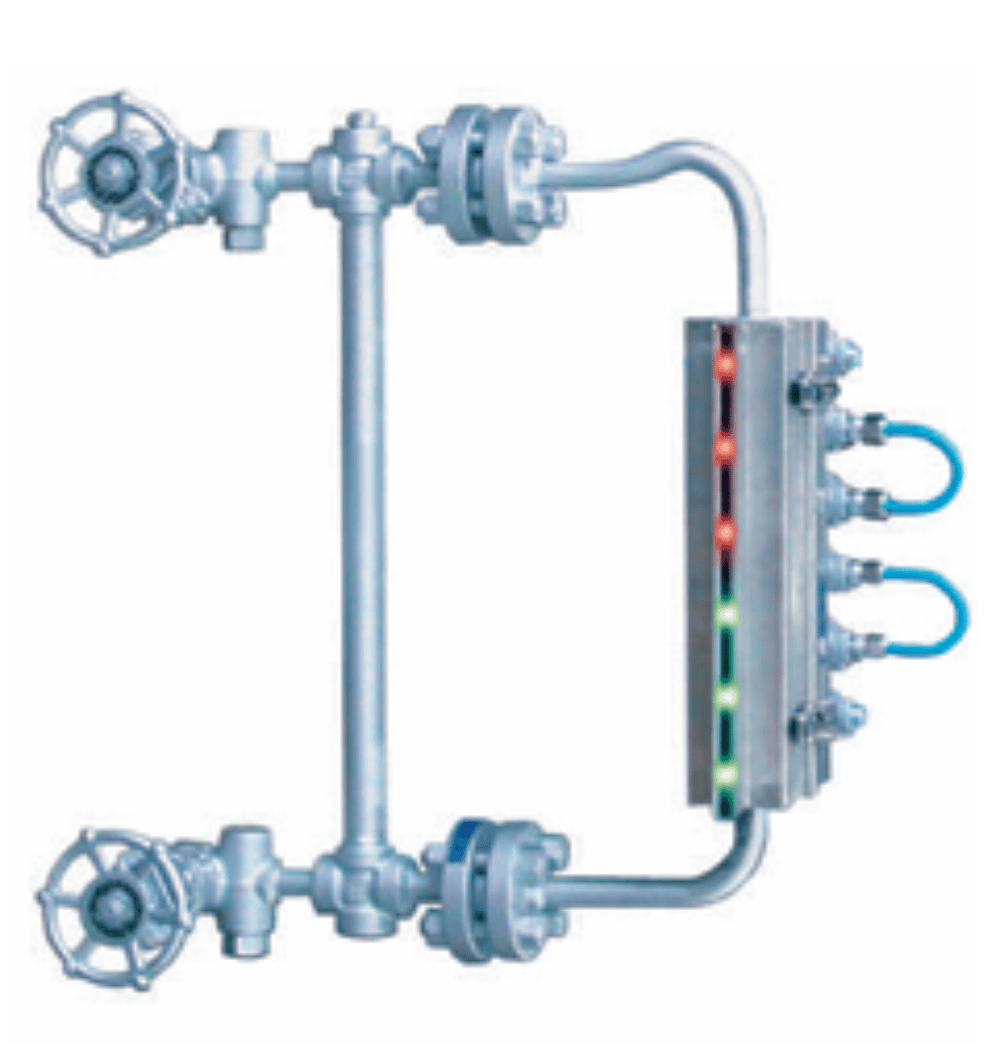

Bicolour level gauges series BC

DESIGNED FOR WATER/STEAM MEASUREMENT Red signal for steam and green signal for water Materials: stainless steel and carbon steel Suitable for saturated steam up to 225 bar (3000 psi) OPTIONS: antifrosting blocks, heating, illuminator (also explosion proof), etc

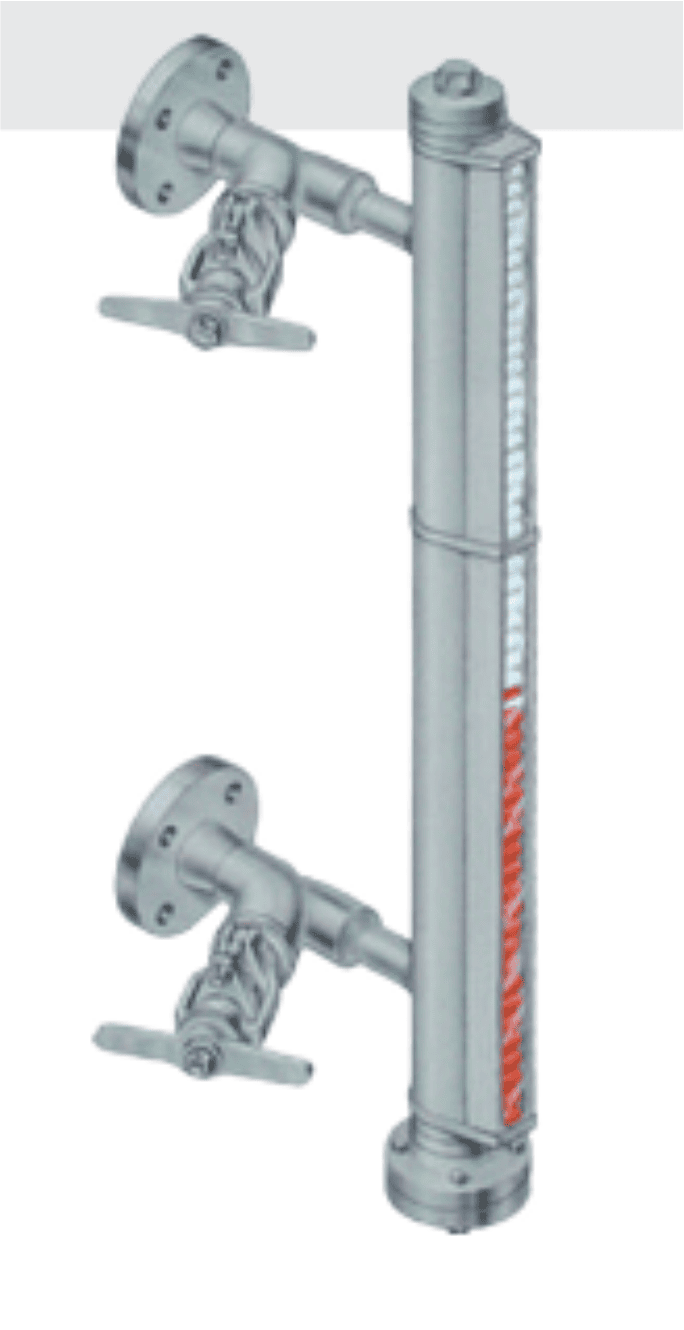

Magnetic Level Gauges series MAG

SUITABLE FOR ANY FLUID, UP TO MOST SEVERE OPERATING CONDITION Able to indicate the separation level between two liquids Materials: stainless steel, special alloys, titanium, plastics. Rating: ASME Class 150 to 2500 (from PN 10 to PN 420) Also with immersed float or ground-floor reading OPTIONS: antifrosting blocks, heating, magnetic switches, con tinuous remote signal transmission (explosion proof on request), etc.

Remote levele transmitter series MST

CAN BE USED ALONE OR CONNECTED TO MAG SERIES MAGNETIC LEVEL GAUGES Continuous analog signal with two wire connection (4÷20 mA) On request digital protocol (HART, Profibus, etc.) Long distance question/replies with SMS/GPRS. Standard resolution 7.5 mm, lower on request Up to 6000 mm useful measuring range Explosion proof available on request

Conductive probe level indicator series RLG

FOR WATER/STEAM MEASUREMENT UP TO SATURATED STEAM (225 BAR) From 10 up to 32 probes Redundant circuits and self-diagnostic equipped for maximum reliability Bicolor signal LEDS and graphic display Analogic signal (4÷20 mA) and digital signal (HART, Profibus, etc) Configurable free exchange contacts

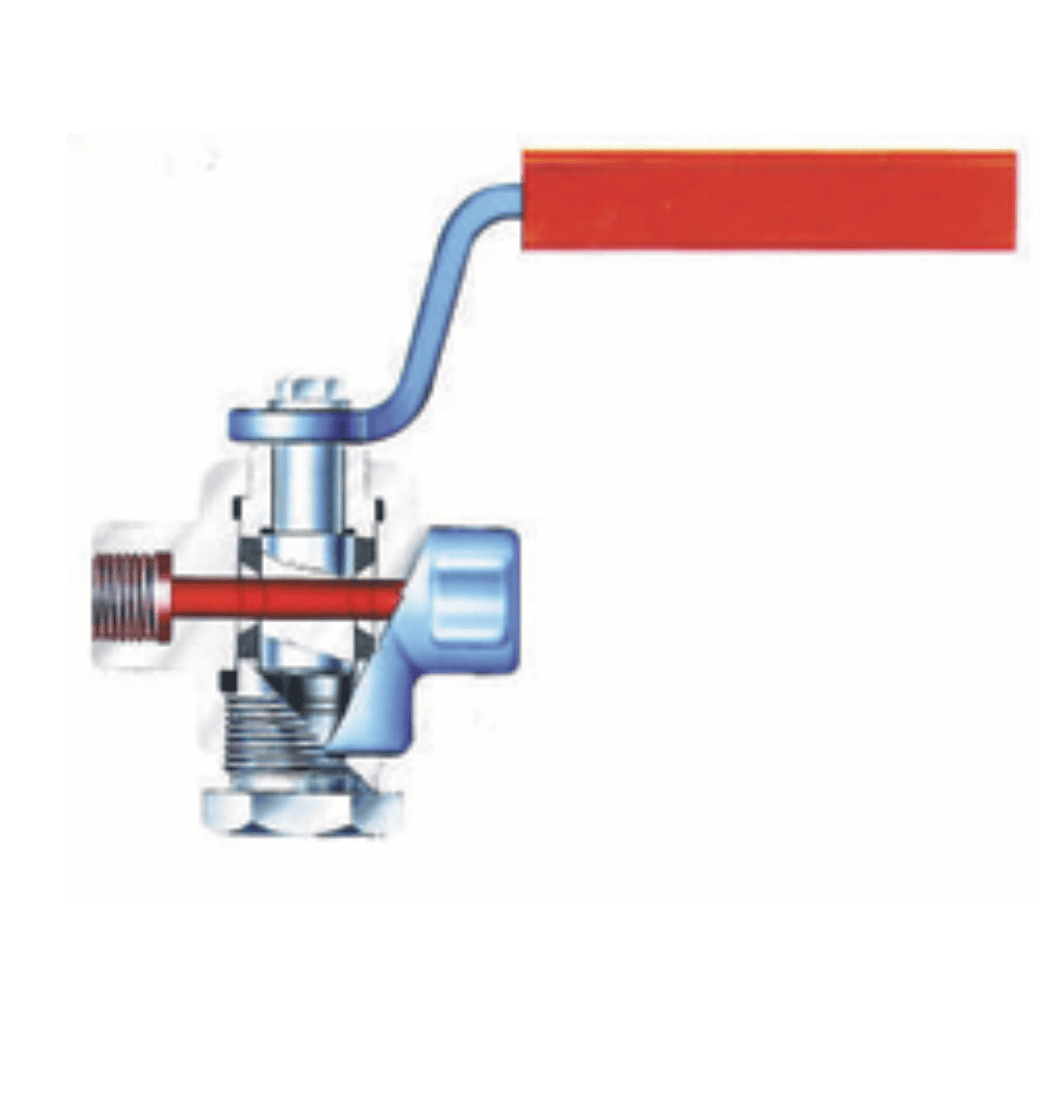

Sleeve-Packed Cocks type RM

MATERIAL: CARBON STEEL, STAINLESS STEEL Operating Conditions: PN 16-25-40-100-160; ASME Class 300-600-900 Size: DN 5 to 25 (1/4” to 1”) Three-way on request Spare Packing Sleeves

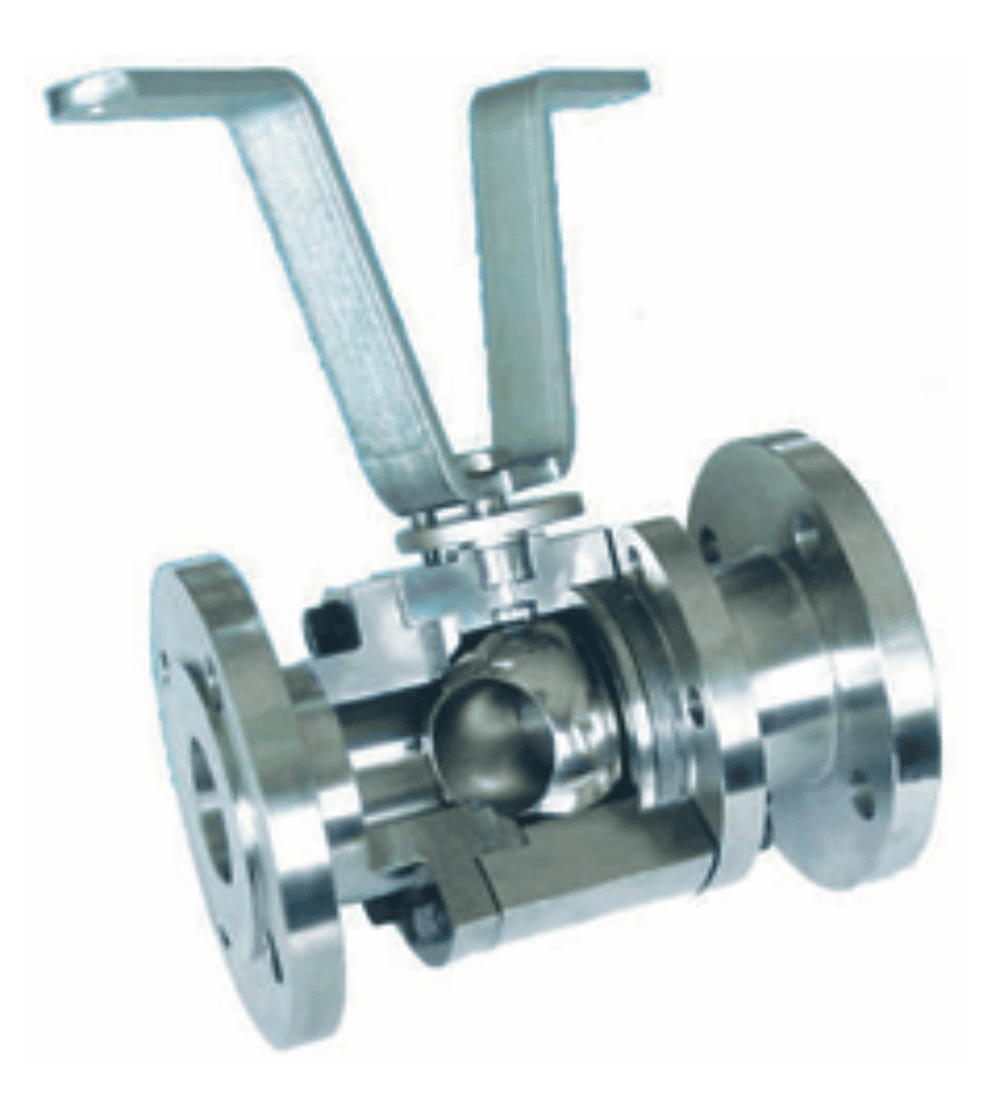

BONT-HTB forged steel ball valves

THREE-PIECE BOLTED CONSTRUCTION - “FIRE SAFE” AND “TA-LUFT” APPROVED Materials: Carbon Steel, Stainless Steel Operating Conditions: PN 40-63-100; ASME Class 150-300-600-800 Size: DN 1/4” to 4” Also with Actuator - Special Model as Boiler Blowdown Valve

BONT-WVE forged steel ball valves

STANDARD AND SPECIAL VALVES - FOR HIGH TEMPERATURE Trunnion or floating type - Soft seated or metal to metal Two or Three-pieces construction - “Fire safe” Materials: Carbon Steel, Stainless Steel, Duplex, Special Alloys, Titanium etc. Operating Conditions: PN 16-100; ASME Class 150-2500 - API 2000-10000 Size: DN 1/4” to 32”

Triple offsett butterfly valves series TOV28000

METAL SEATED, BI-DIRECTIONAL, BUBBLE-TIGHT (ZERO LEAKAGE) ACCORDING TO API 598 AND API 6D Construction according to API 609, Fire Safe secondo API 6FA Materials: Carbon Steel, Stainless Steel, Alloy Steel or special Alloys - Duplex, Monel, Hastelloy, etc. Cryogenic Application: up to -196 °C Rating: ASME Class 150-300-600-900-1500 Size: DN100 to DN2800 (4” to 112”)

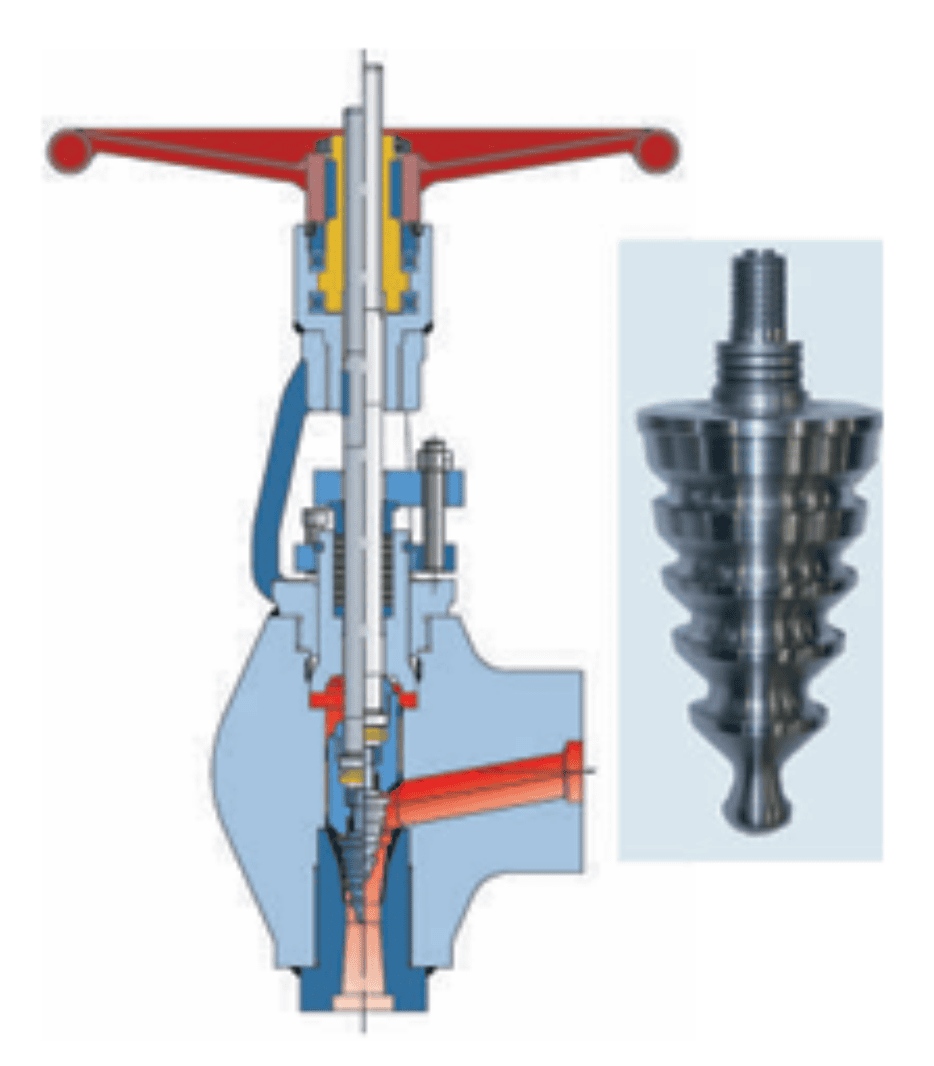

Piston Valves series BV

BUBBLE-TIGHT (ZERO LEAKAGE) AT LOWEST AND HIGHEST TEMPERATURES No fugitive emissions (TA-Luft and fire-safe certified) Approved for the handling of liquefied gases on railway tanks Available with flow regulating trim Special multilayer seats suitable from -196 °C up to +550 °C and over. Rating: ASME Class 150 ÷ 600 (PN16 ÷ PN63) and API 800. Size: 1/2“ up to 8“ (from DN15 up to DN 200)

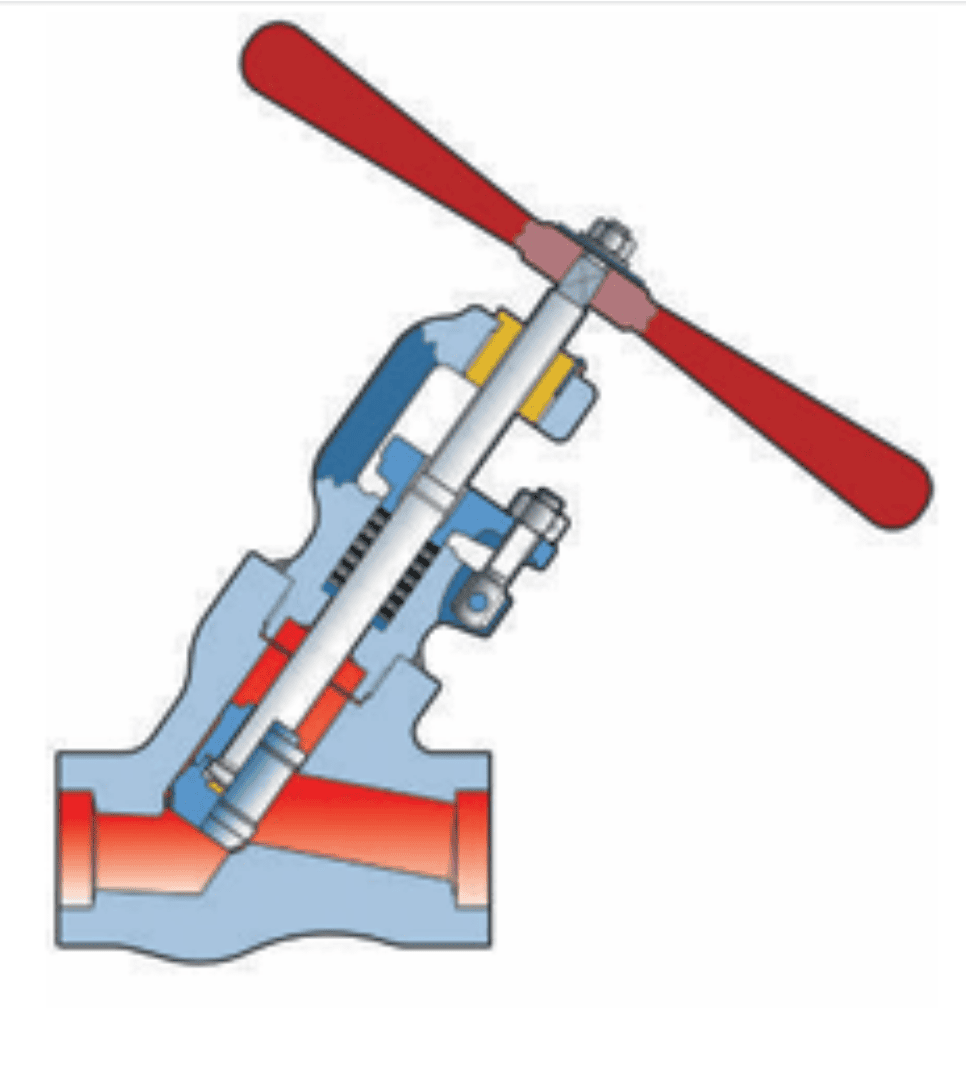

Forged “Y” pattern valves series WBY

LESS FLUID TURBULENCE AND HIGHER FLOW COEFFICIENT Stop, or piston check, or flow control, or stop-check Available in special designs and materials for any fluid. Available with electric or pneumatic actuator on request ASME Class 600-900-1700-2700-4500 and special Classes. Size: 1/4” up to 4”

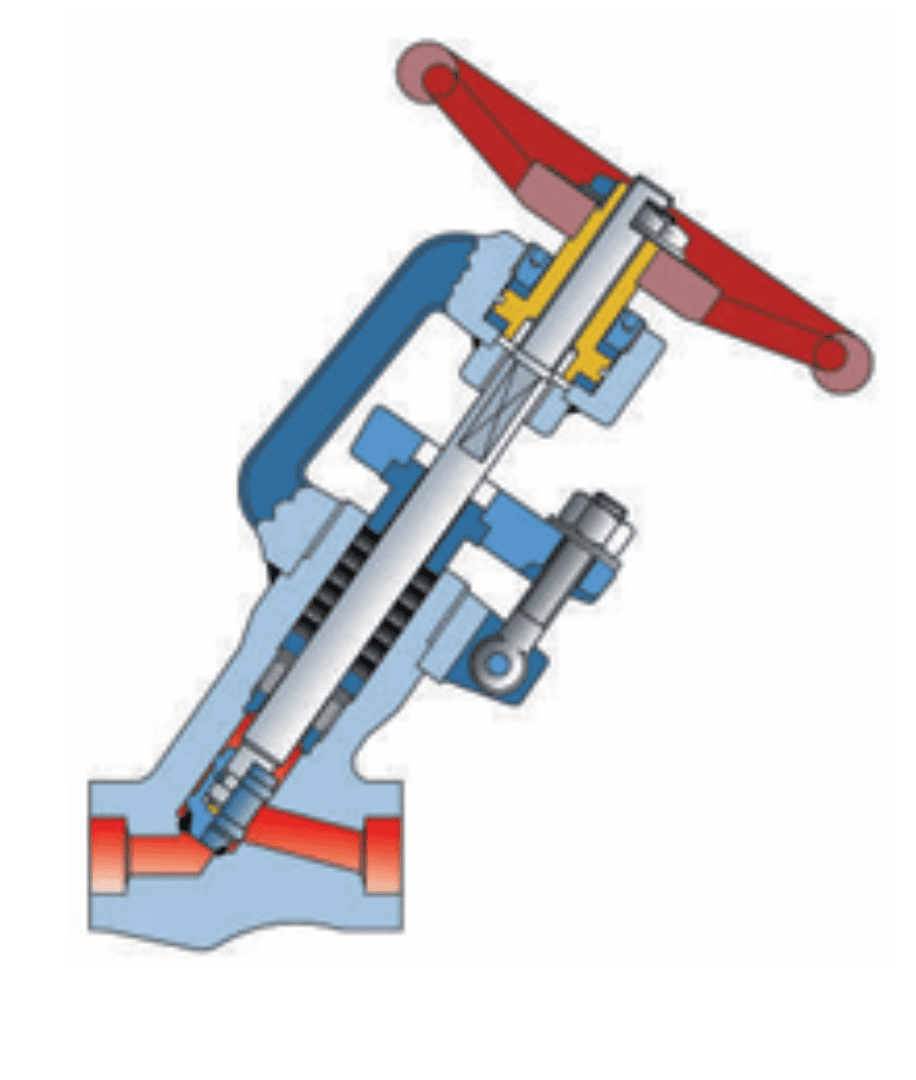

Forged “Y” pattern valves series BLY

BONNETLESS - RISING, NON ROTATING STEM Stop, or piston check, or flow control, or stop-check. Special anticavitation trim on request. Available in special designs and materials for any fluid Available with electric or pneumatic actuator on request ASME Class 1700-2700-4500 Size: 1/2” up to 3”

Special BONETTI valves series SV

CUSTOM MADE VALVES FOR SEVERE DUTY APPLICATIONS Valve type: stop, throttling, check Suitable for urea and fertilizer application, water treatment plants, hazardous fluids Available in various executions and materials, also special alloy On request, available with electric or pneumatic actuator Designed according to unique Customer and plant requirements

Quick acting automatic valves series AV2 and AV3

TYPE TWO WAYS (AV2) OR THREE WAYS (AV3) Designed for H.P. preheaters bypass systems Hydraulically self-actuated by the process media Operating speed controlled by an external regulating valve Manual operation with locking device ASME Class 900-1500-2500 and special Classes. Nominal diameters up to 18” size

Blowdown & blowoff valves series BLB, PBR & RSS

FOR CONTINUOUS (BLB) OR DISCONTINUOUS (PBR) OR INTERMITTENT BLOW-OFF Useful for flow control under high differential pressure Needle type (BLB), tandem type with multistage disk (PBR), or ball type (RSS and RSSA). Available with actuator ASME Class 600-800-900-1700-2700-4500 and Special Classes. PN 40-63-100-160 250-420-630-760.

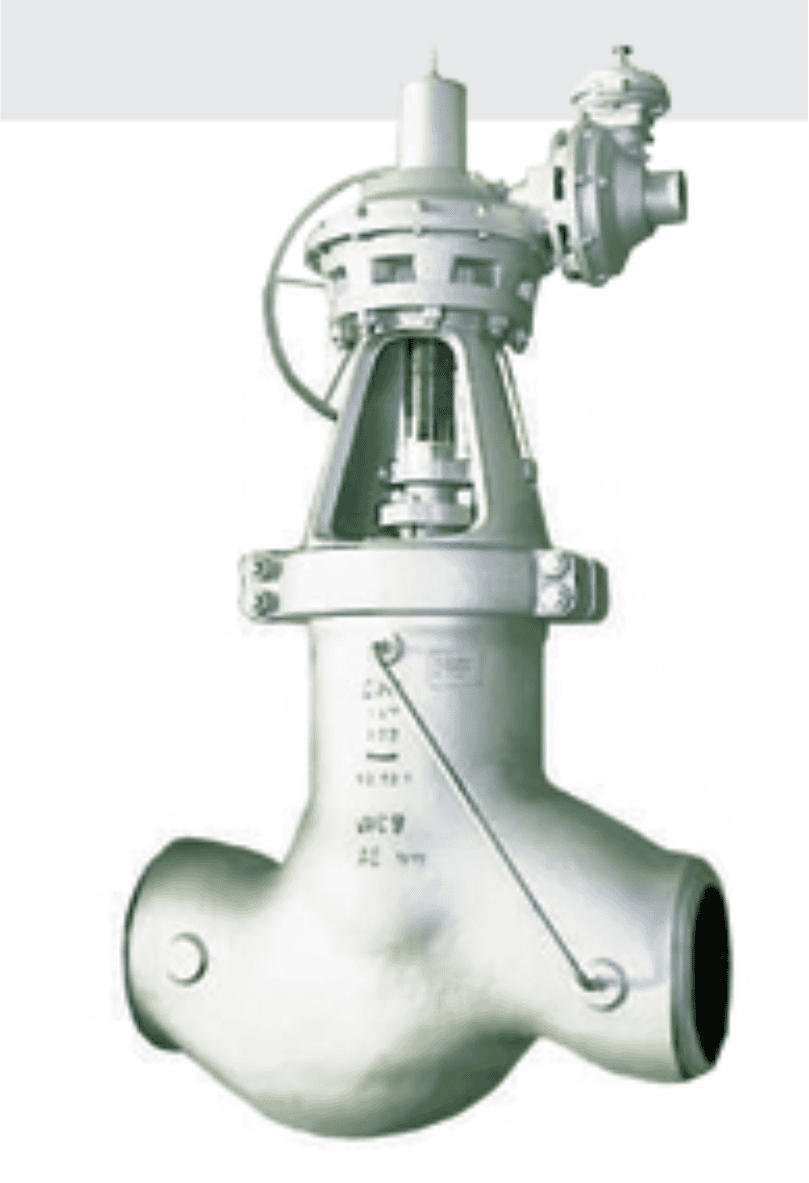

High pressure gate valves series CMI-S

PRESSURE SEAL Split wedge or Parallel slide Hand operated or actuated (electrically or pneumatically) Bypass and/or equalizing pipe on request ASME Class 600-900-1500-2500-4500 and special Classes. Size: 2” up to 28”

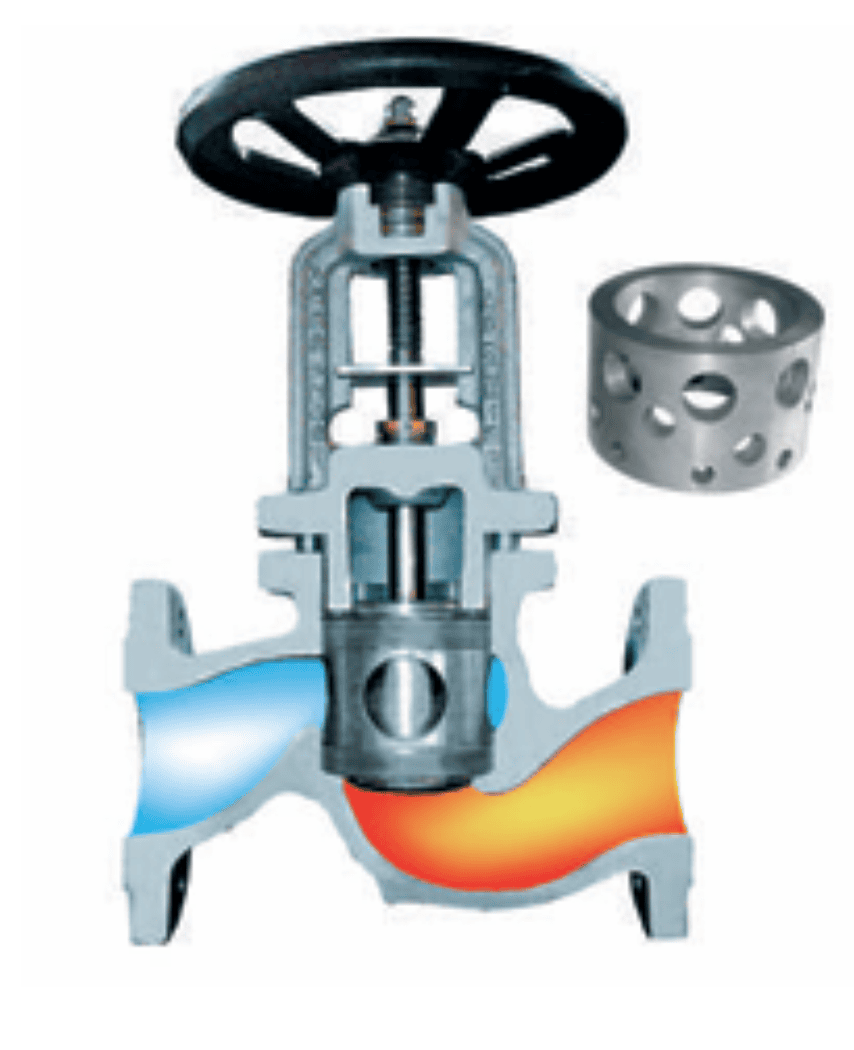

High pressure globe valves series CMI-G

PRESSURE SEAL Construction: “T” type, “Y” type, angle, “Elbow down” Stop, throttling, stop check, piston check. Hand operated or actuated (electrically or pneumatically). ASME Class 600-900-1500-2500-4500 and special Classes Size: 4” up to 24”

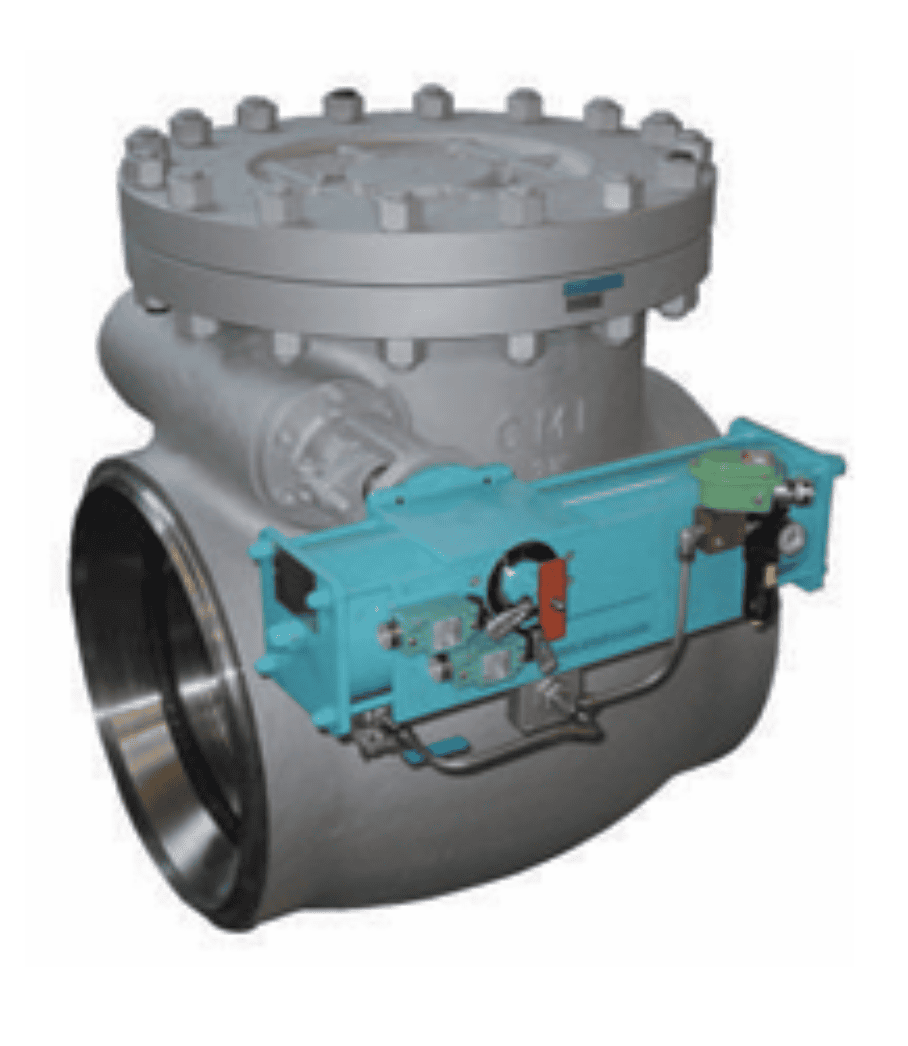

High pressure check valves series CMI-C

VERTICAL SEAT (PERPENDICULAR TO FLOW), HIGHER FLOW COEFFICIENT Pressure seal or bolted bonnet Swing or tilting disk Available pneumatically actuated (for turbine bleeding lines) ASME Class 150-300-600-900-1500-2500-4500 Size: 2” to 48”